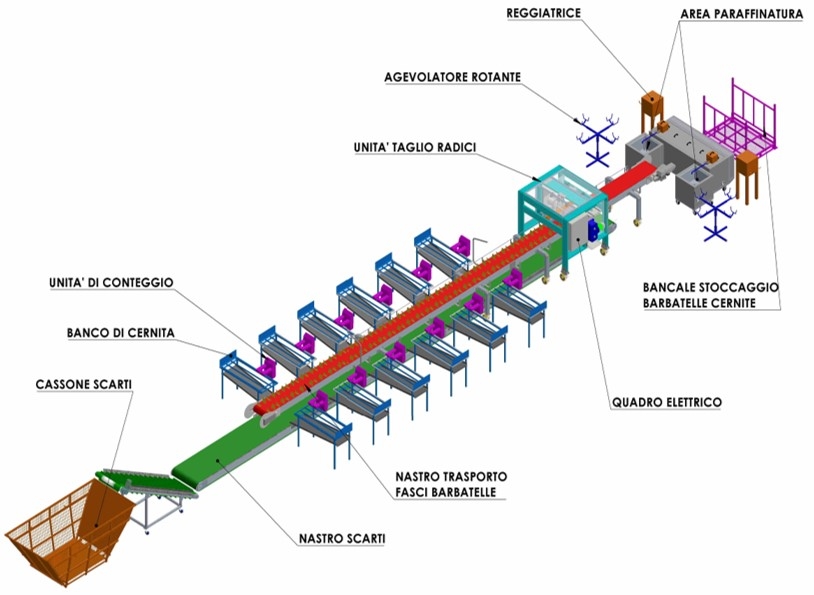

HECO-CERNITA

The Sorting is the working process during which, after the "digging out" of the Barbatelle or grafted vines, the quality control phase and all the activities that come before the storing of the final product take place, that is: trimming of the exceeding shoots, roots cutting, final waxing and strapping. These activities are very often cause for mistakes due to the repetitiveness of the actions, also considering that each single operator handles thousands of grafted vines every day.

Thanks to the Sorting Line HECO-CERNITA, it is possible to organize all these activities in a rational and ergonomic way so that the movement of people and product is reduced to a minimum, in order to avoid the above-mentioned mistakes and therefore reducing costs by more than 30%.

The Sorting Lines conceived by Zetaecotech consist in mobile or tipping Working Desks HECO-BANCO, where the manual trimming of the exceeding shoots takes place and where, thanks to the Counting Unit HECO-COUNTER, the bundles of Barbatelle are accurately counted and correctly formed (e.g.: 25 per bundle). Afterwards, the bundles are placed on a Transport Belt HECO-NASTRO-V01 which will transport the grafted vines bundles towards the Cutting Unit HECO-TAGLIO for the automatic cutting of the roots at the desired length, from here the bundles will come out to be finally waxed at the manual Double Waxing Station HECO-A-800, before being tied with the semi-automatic strapping machine HECO-TIE. Ultimately, the bundles of Barbatelle will be placed in the metal racks HECO-CONTAINER, ready for storage.

In its full version, the Sorting Line Zetaecotech can be equipped with a secondary Transport Belt HECO-NASTRO-V02 positioned under the main Sorting Belt, in order to collect and convey all the shoots and roots scraps towards a pre-arranged collector.

Il this way, it is possible to avoid both the accumulation of waste in the surrounding working area and the interruption of working activities for cleaning up.

The Sorting Lines Zetaecotech are 100% customizable according to the customer’s needs.

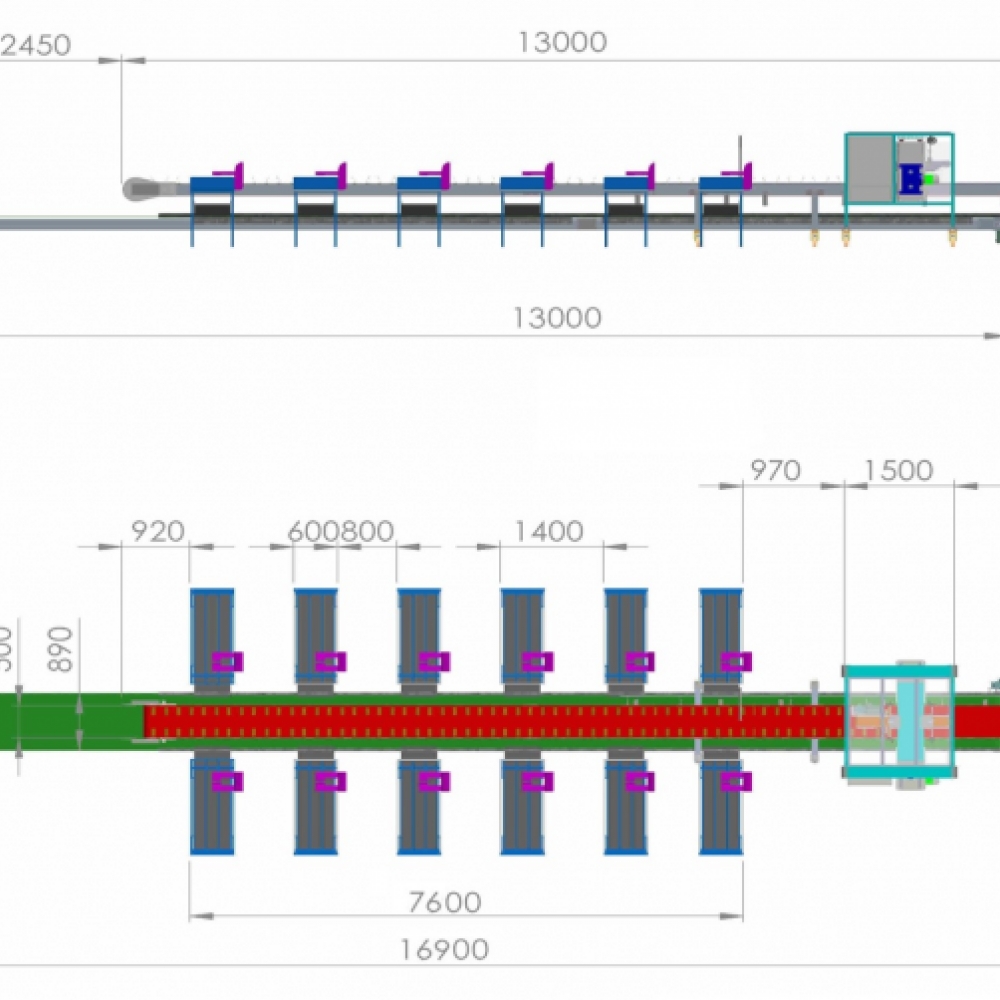

- MAIN TRANSPORT BELT FOR GRAFTED VINES BUNDLES: NR. 1 MODULAR BELT IN PROFILED ALUMINIUM ON PIVOTING WHEELS WITH ADJUSTABLE HEIGHT AND SPEED AND STAINLESS STEEL FLIGHTS TO CONVEY THE BUNDLES

- WORKING STATIONS: NR. 12 OR 24 MOBILE WORKING DESKS WITH ADJUSTABLE HEIGHT OR FIXED TIPPING DESKS ANCHORED TO THE MAIN BELT

- COUNTING SYSTEM: NR. 12 OR 14 COUNTING UNITS WITH PROGRAMMABLE LOGIC CONTROLLER AND ELECTRO-MECHANICAL LOCK

- ROOTS CUTTING SYSTEM: SINGLE OR DOUBLE CUTTING UNIT (LEFT AND RIGHT) WITH SPECIAL STAINLESS STEEL CIRCULAR SEGMENTED BLADES - ADJUSTABLE CUTTING POSITION AND ELECTRONICALLY CONTROLLED SPEED

- WAXING SYSTEM: DOUBLE WAXING STATION CONSISTING OF NR. 1 MAIN WAXING MACHINE FOR WAX MELTING AND OF NR. 2 TANKS FOR BUNDLES WAXING, PUMPS FOR WAX AGITATION AND TRANSFER

- STRAPPING SYSTEM: SEMI-AUTOMATIC BINDING OF THE GRAFTED VINES BUNDLES WITH THE VERTICAL STRAPPING MACHINE

- SECONDARY TRANSPORT BELT FOR WASTE: NR. 1 MODULAR BELT IN PROFILED ALUMINIUM WITH ADJUSTABLE HEIGHT AND SPEED

- TRANSPORT BELT FOR THE FINAL UNLOAD OF WASTE INTO THE COLLECTING DUMPSTER: NR. 1 MODULAR BELT IN PROFILED ALUMINIUM WITH ADJUSTABLE HEIGHT AND SPEED

- ELECTRICAL POWER: 11,0 - 12,5 KW DEPENDING ON THE VERSION

- TOTAL DIMENSIONS: LC-12 L. 16.900 x W. 3.800 x H. 2.200 mm LC-24 L. 28.500 x W. 3.800 x H. 2.200 mm